Cooling water piping system chemical site

Critical cooling water pipes

Critical cooling water pipes

Amerplastics implemented highly critical cooling water pipes within the process installation framework at the chemical site in question with the Bondstrand 2000 and 2416 Glass fibre Reinforced Epoxy (GRE) piping system with Quick-Lock and Taper/Taper adhesive joints.

The new cooling water pipes were installed due to a capacity expansion (from 340,000 tonnes to 570,000 tonnes) of the existing production plant. Per hour, 4,500 m³ of water flows into this production facility, which is the client’s largest Polyol plant worldwide.

A total of 160 tonnes of primary ‘pipe shoes’ and secondary steel structures were designed, prefabricated, and installed. Amerplastics’ installation crews worked safely for 40,000 hours. Our project management attended around 450 construction meetings.

The project was divided into six sub-projects:

- 1681:OSBL 36″ (part 1) cooling water pipe

- 1681A: ISBL connection during shutdown

- 1681B: ISBL shutdown and connection to E-735

- 1681C: OSBL 36″ (part 2) and 20″ pipe to Biox outlet

- 1681D: OSBL 30″ inlet pipes at jetty area

- 1681E: ISBL 4”-20” Polyurethane plant

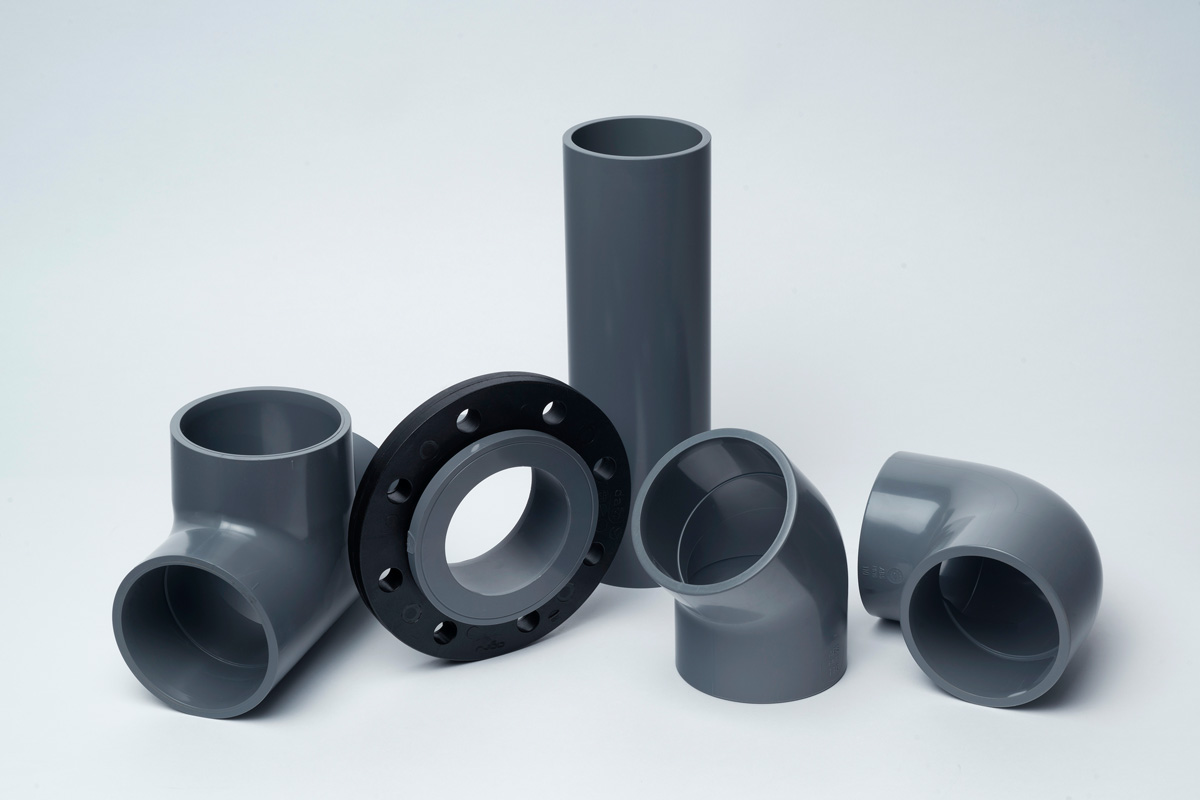

Piping systems

Service : Coolingwater

Product : Bondstrand 2000 en 2416

Diameter : 4 to 36 inch (100 – 900 mm)

Total size : 3,400 metres of pipes and 1,250 fittings

Operational conditions

Design pressure: 10 bar

Operating pressure: 5 bar

Design temperature: 50 degree Celsius

Vacuum resistance: Safety factor = 1.5

Operating temperature: ambient

Benefits realised

- Proven reliability of existing Bondstrand systems

- Corrosion-resistant piping system

- Lower cost of ownership

- Maintenance-free

Other projects

Other projects

Get in touch with Amerplastics experts

Get in touch with Amerplastics experts