Thermoplastics

Thermoplastics

Thermoplastics are pliable polymers. They are often shaped by melting them and injecting them into a mould. Thermoplastics have the great advantage that the softened polymers can easily be shaped into a particular shape. Moreover, they can be easily reused. Many products such as plastic bags, toys, and polystyrene are made of thermoplastics.

High-Density Poly Ethyleen (HDPE)

High-Density Poly Ethyleen (HDPE)

HDPE is widely used for transporting water and gases, acids and alkalis up to around +60°C. The material is flexible at lower temperatures, impact resistant, and has good electrical properties. HDPE is a durable material that can take a beating. It is relatively flexible material that is very suitable for long-term use. Not only is it resistant to stress, it is also hardly subject to chemical corrosion. Bacteria and dirt find it difficult to adhere to polyethylene.

HDPE are excellent for use in wire welding, extrusion welding, butt welding, socket welding, and/or electrofusion welding.

Applications

Applications

HDPE pipes are used for water pipes, gas pipes, sewage pipes, pipes for sludge transfer, rural irrigation, pipes for supplying fire-extinguishing systems, electricity and communication pipes, and rain and drainage pipes.

Polypropylene (PP)

Polypropylene (PP)

This versatile plastic has a high temperature range, is lightweight, and has high chemical resistance. In addition, polypropylene is tough, odourless, and taste-free. The processing options are diverse. For example, PP is easy to weld, saw, chip, and can be cut using waterjet and laser beam technology. It differs in physical properties from HDPE and retains good mechanical properties even up to +100°C, which means a stable piping system.

Polypropylene are excellent for use in wire welding, extrusion welding, butt welding, socket welding, electrofusion welding, infrared welding, and/or WNF welding.

Applications

Applications

PP piping systems are mainly used in systems with higher concentrations of acids combined with higher temperatures. However, the maximum temperature to be used must be observed as a function of the concentration of the medium. Furthermore, there is good resistance to alkalis and non-oxidising salt solutions.

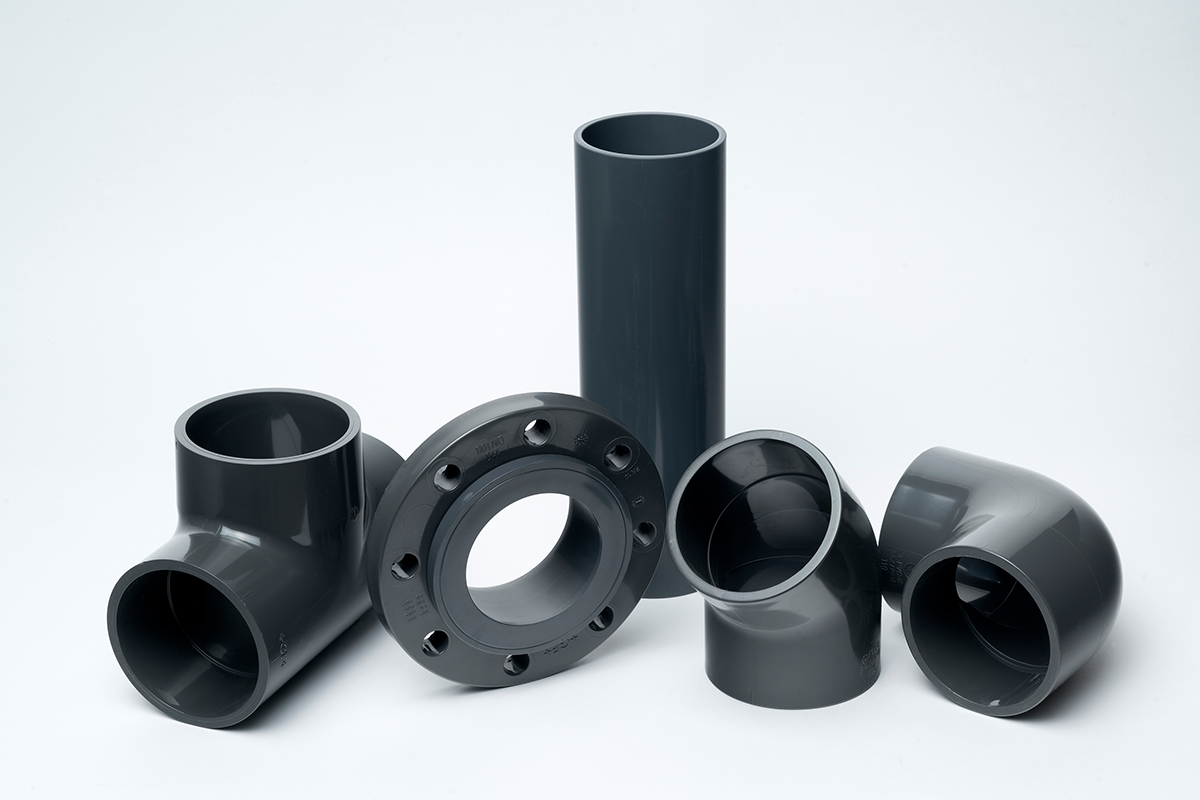

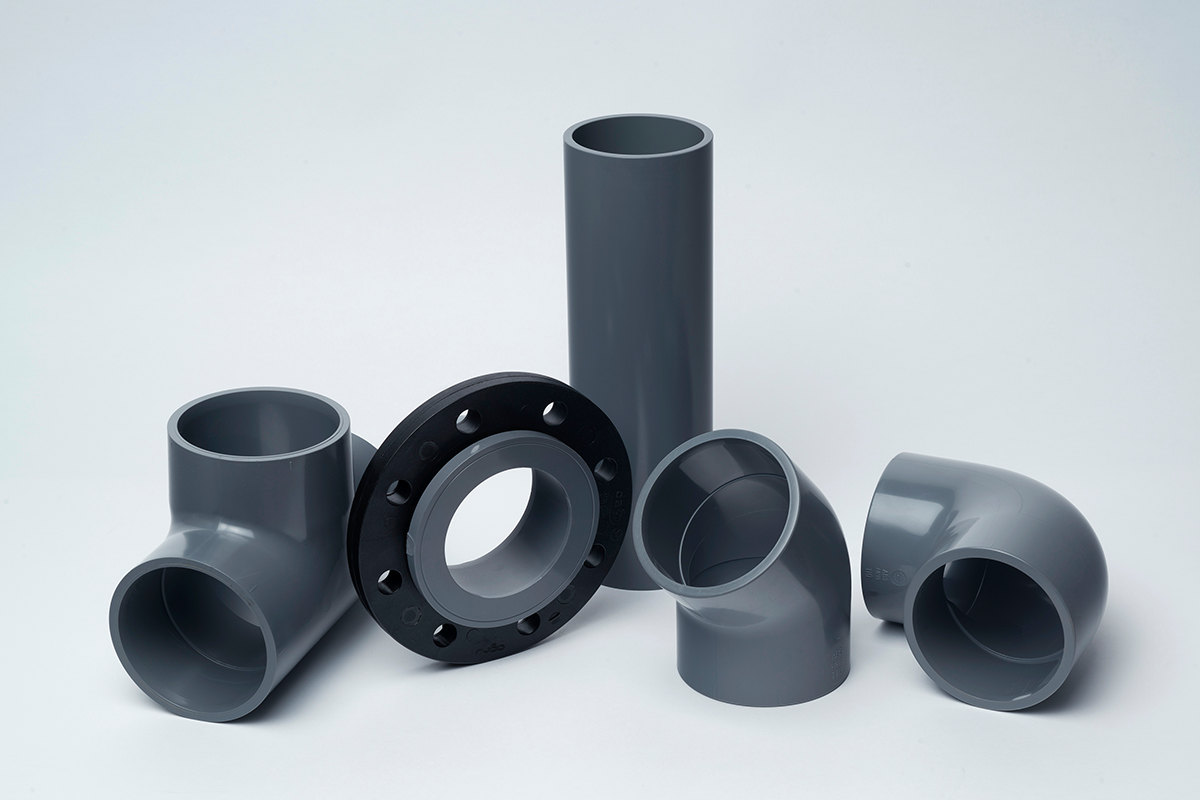

Poly Vinyl Chloride (PVC)

Poly Vinyl Chloride (PVC)

PVC can be divided into PVC-C and PVC-U. The main difference between these two types of piping systems is temperature resistance.

PVC-C piping materials have an operating temperature range of 0 to +80°C. Mechanical properties such as high strength, stiffness, and good impact resistance in particular are a major advantage at higher temperatures. Our PVC-C pipes are also characterised by their self-extinguishing properties. PVC bonds well, which makes processing easy.

Applications

Applications

PVC-U piping materials have a temperature range of 0 to +60°C. PVC-U has been shown to be physiologically harmless and has very good chemical properties. PVC-U pipes are used in water treatment and the chemical process industry, among others applications.

Acrylonitrile Butadiene

Styrene (ABS)

Acrylonitrile Butadiene

Styrene (ABS)

ABS is a tough and hard plastic that has excellent chemical and electrical properties. The main difference compared to other plastics is temperature resistance (-50°C, max. +60°C) and exceptional dimensional stability at lower temperatures.

ABS piping systems offer an energy-efficient solution in refrigeration and air-conditioning technology. ABS can be used in a wide temperature range from -50°C to +60°C thanks to its favourable material properties. ABS pipes can be bonded excellently with special ABS glue.

Applications

Applications

ABS piping systems are widely used in water treatment, plant engineering, and the food industry.

Used in following sectors

Used in following sectors

The right product for your application

The right product for your application

The right product for your application

The right product for your application

Our experts are happy to help you in coming up with the optimal solution. Contact us to find out more about all the possibilities.