Petrochemical process pipes

Plastic piping system for seawater transport

Plastic piping system for seawater transport

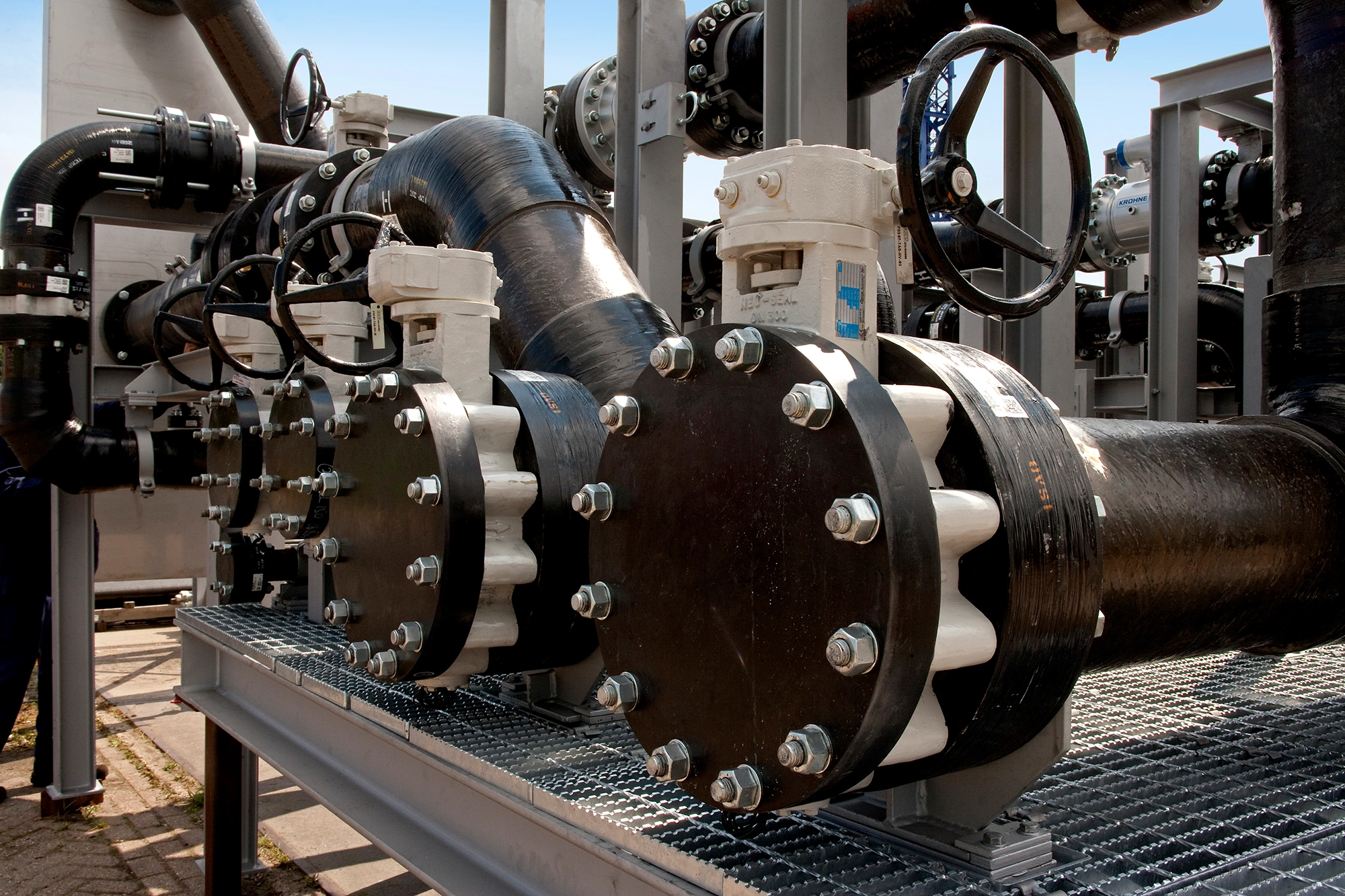

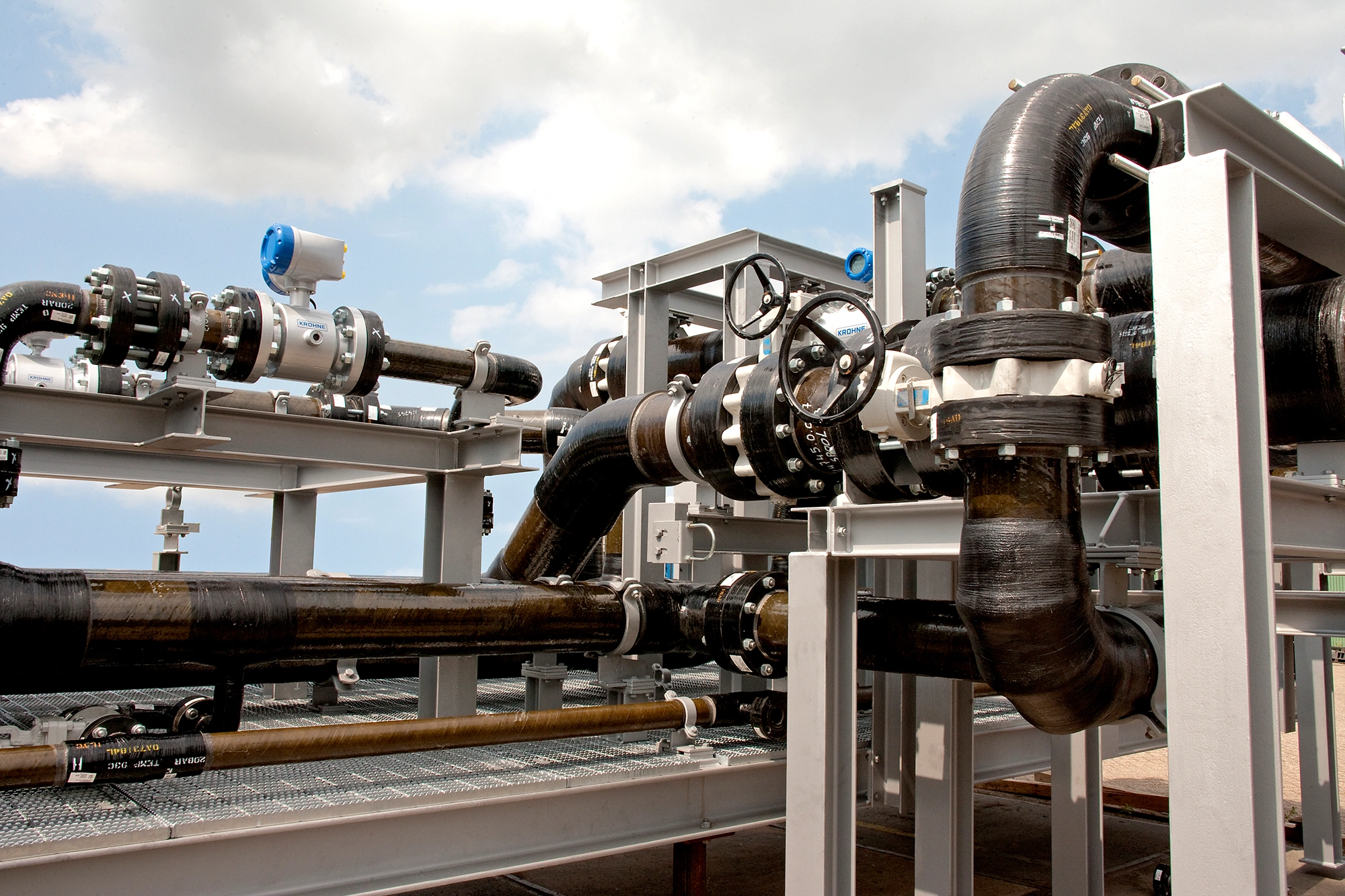

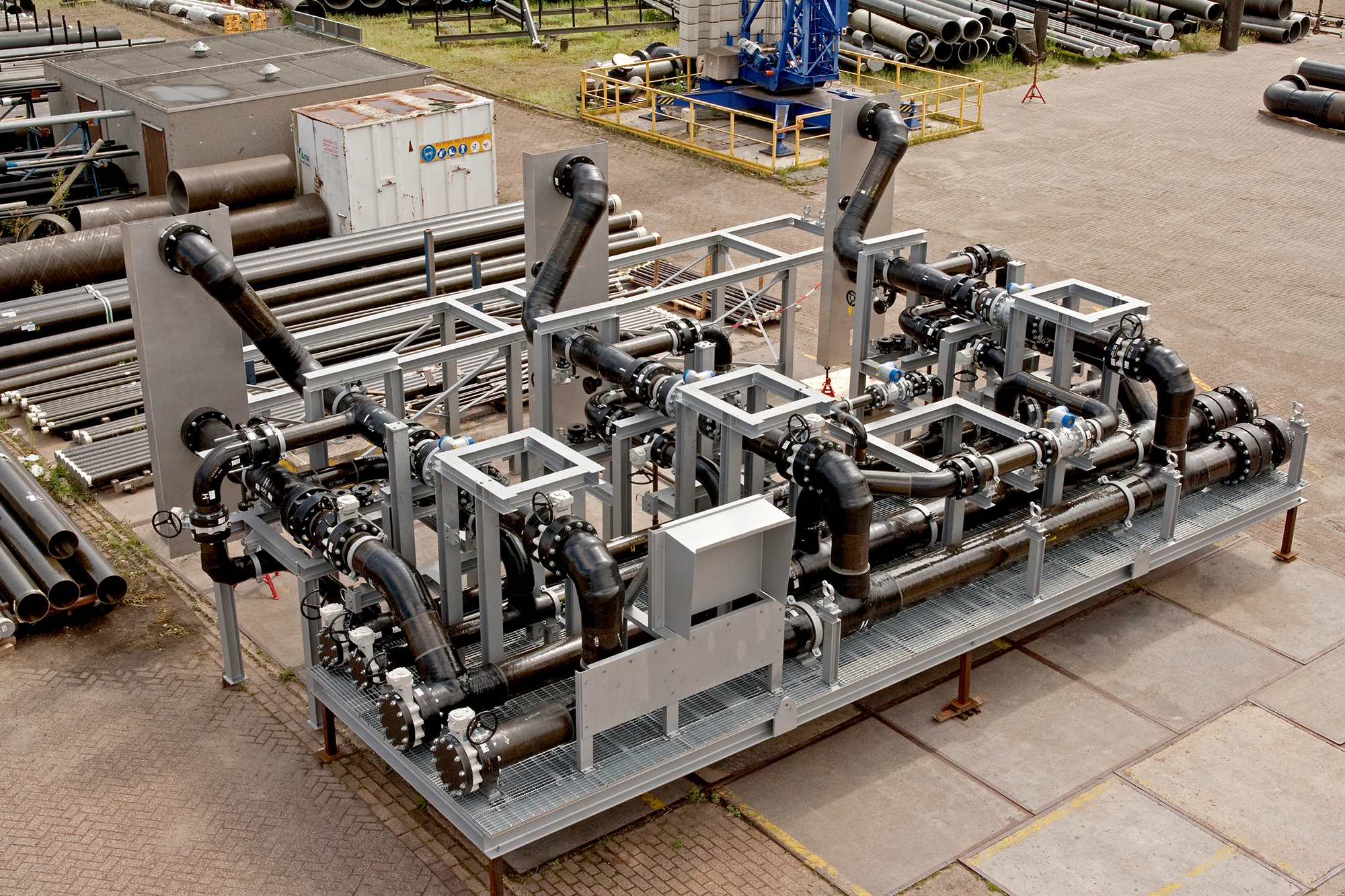

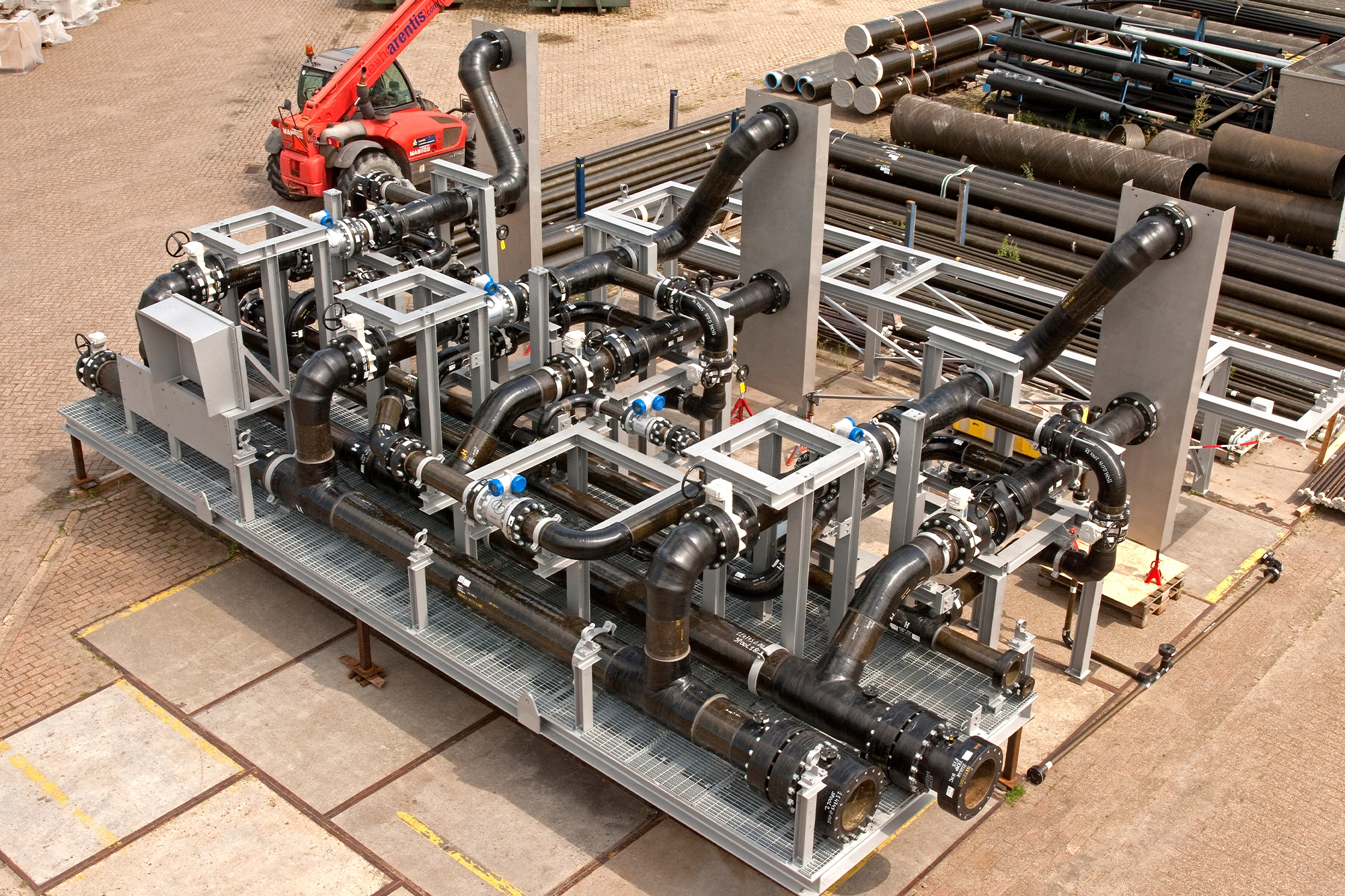

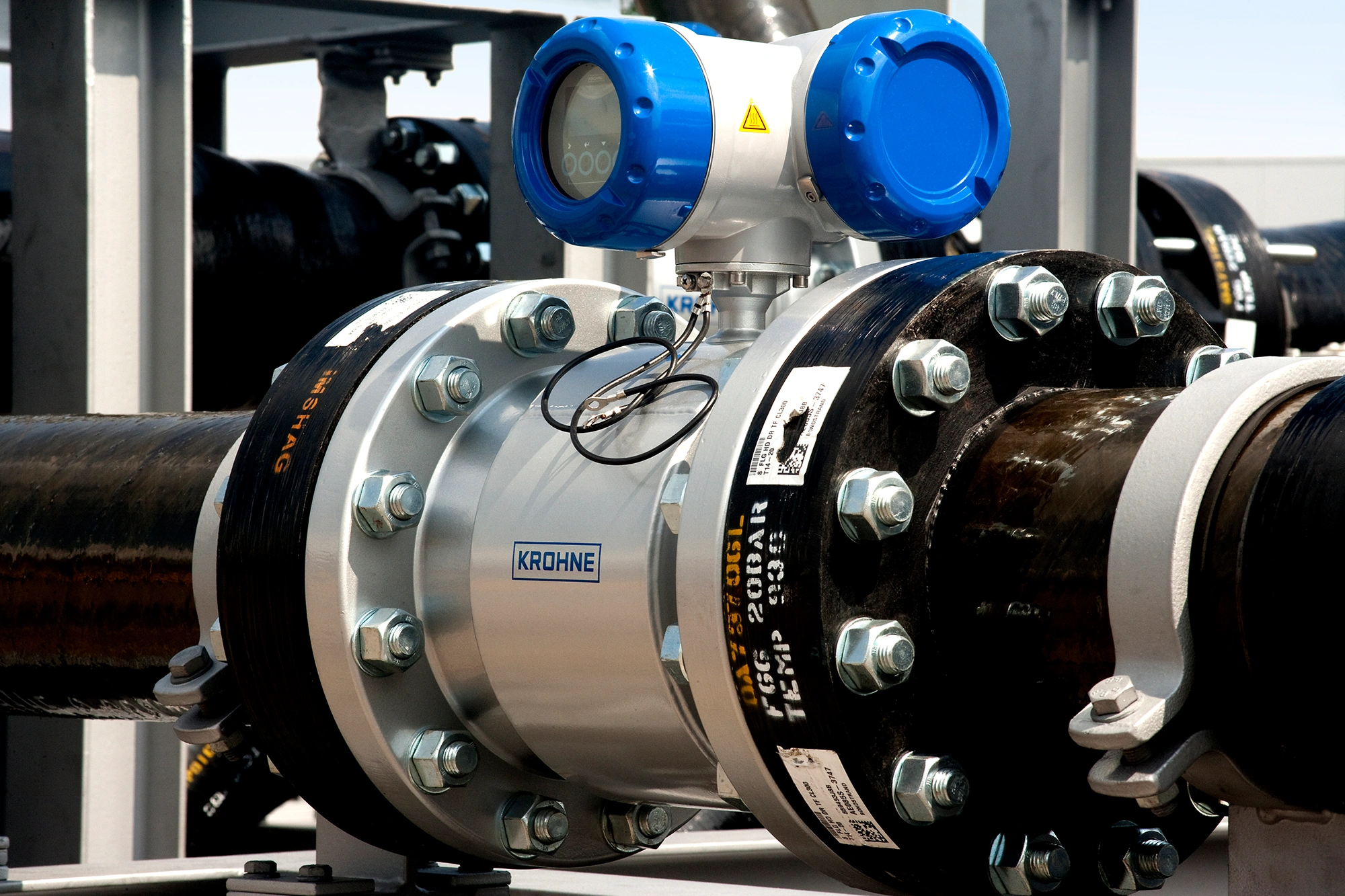

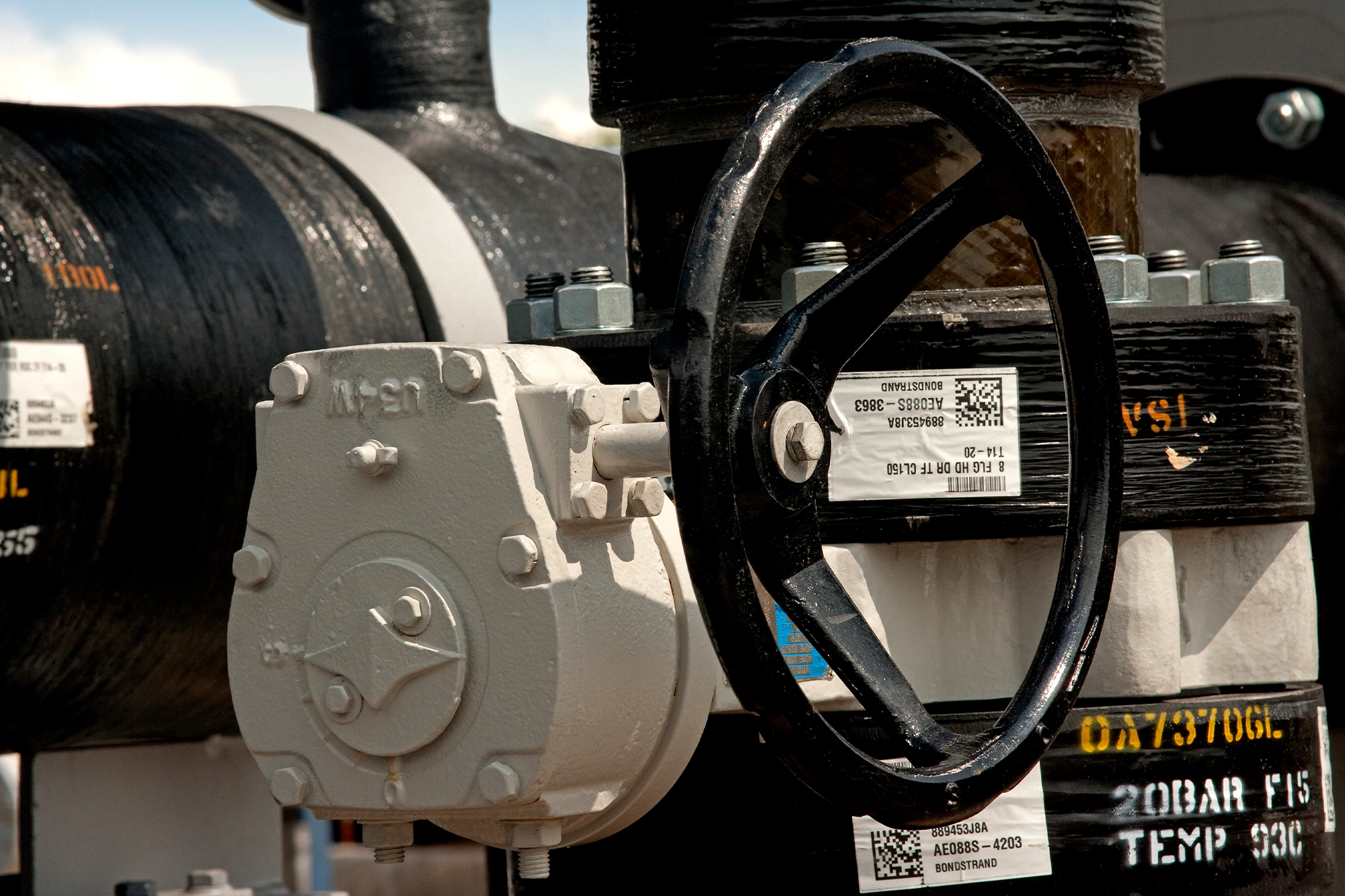

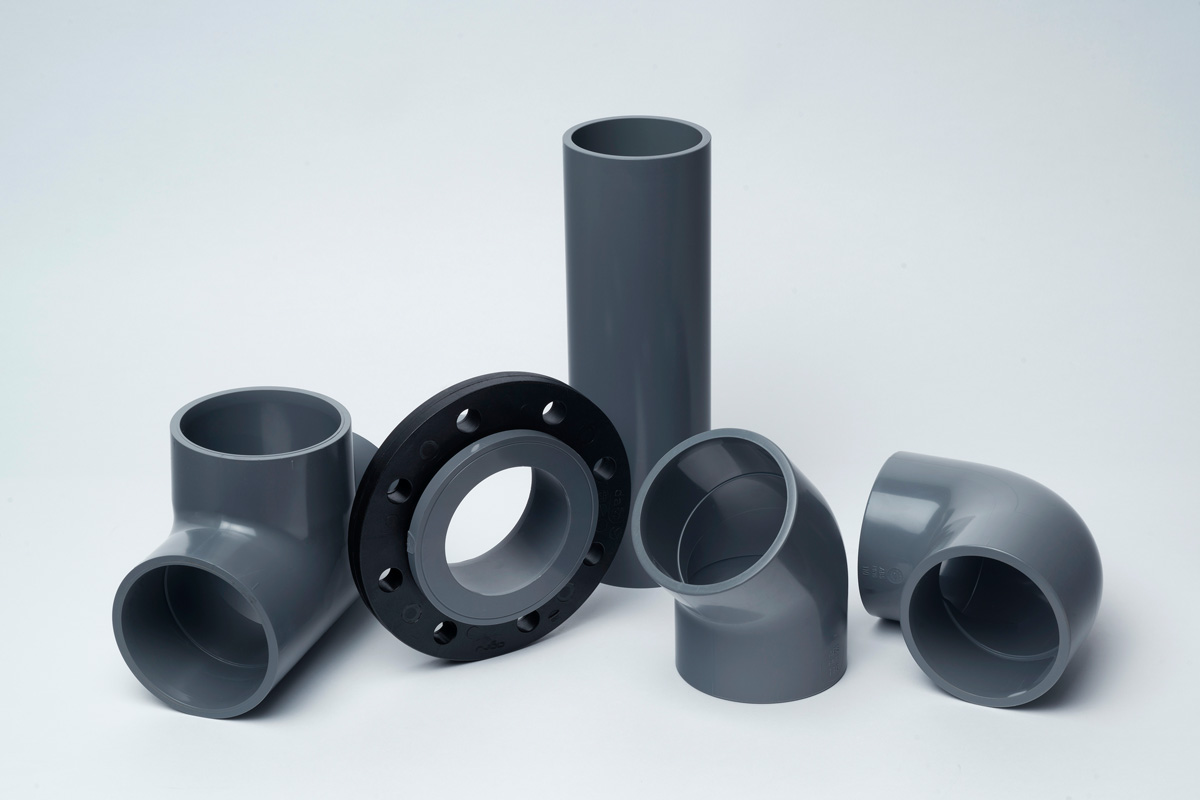

Amerplastics realised process pipes for the transport of salty seawater, using Bondstrand 2420 glass fibre reinforced epoxy (GRE) piping systems with Taper/Taper bonded joints.

The assignment included the complete design, CAD detail drawings, manufacturing, supply, and installation of GRE pipe spools. Ferris Structural Steel, also part of Syndus Group, was responsible for the steel frame.

WARA Pressure Maintenance Project

WARA Pressure Maintenance Project

The system is part of the WARA Pressure Maintenance Project at the Greater Burgan Field in Kuwait. The Greater Burgan Field is the largest sandstone oil field in the world. WARA reservoir is one of the four main reservoirs in the Greater Burgan Field. After 60 years of primary production, the field experienced a significant pressure drop. So, in 2005, a design for a Pressure Maintenance Project (PMP) through peripheral water injection was initiated to counteract the pressure drop and improve oil recovery.

Salt water flows through the Bondstrand GRE intake pipes to the three coupled filtration units. After the filtration process, the water flows through the Bondstrand outlet pipes and is ready to be injected into the oil wells. The sand filtration units can be cleaned by reversing the process. During this reverse process, a gas stream is injected to remove debris from the sand filters. The entire system is PLC controlled.

Piping system

Service: Seawater transport

Product: Bondstrand 2420

Diameter: 2 to 20 inches (20 – 500 mm)

Operational conditions

Design pressure: 20 bar

Operating pressure: 6.5 bar

Design temperature: 60 degrees Celsius

Operating temperature: Ambient

Benefits realised

- Corrosion-resistant piping system

- Lower cost of ownership

- Maintenance-free

Other projects

Other projects

Get in touch with Amerplastics experts

Get in touch with Amerplastics experts