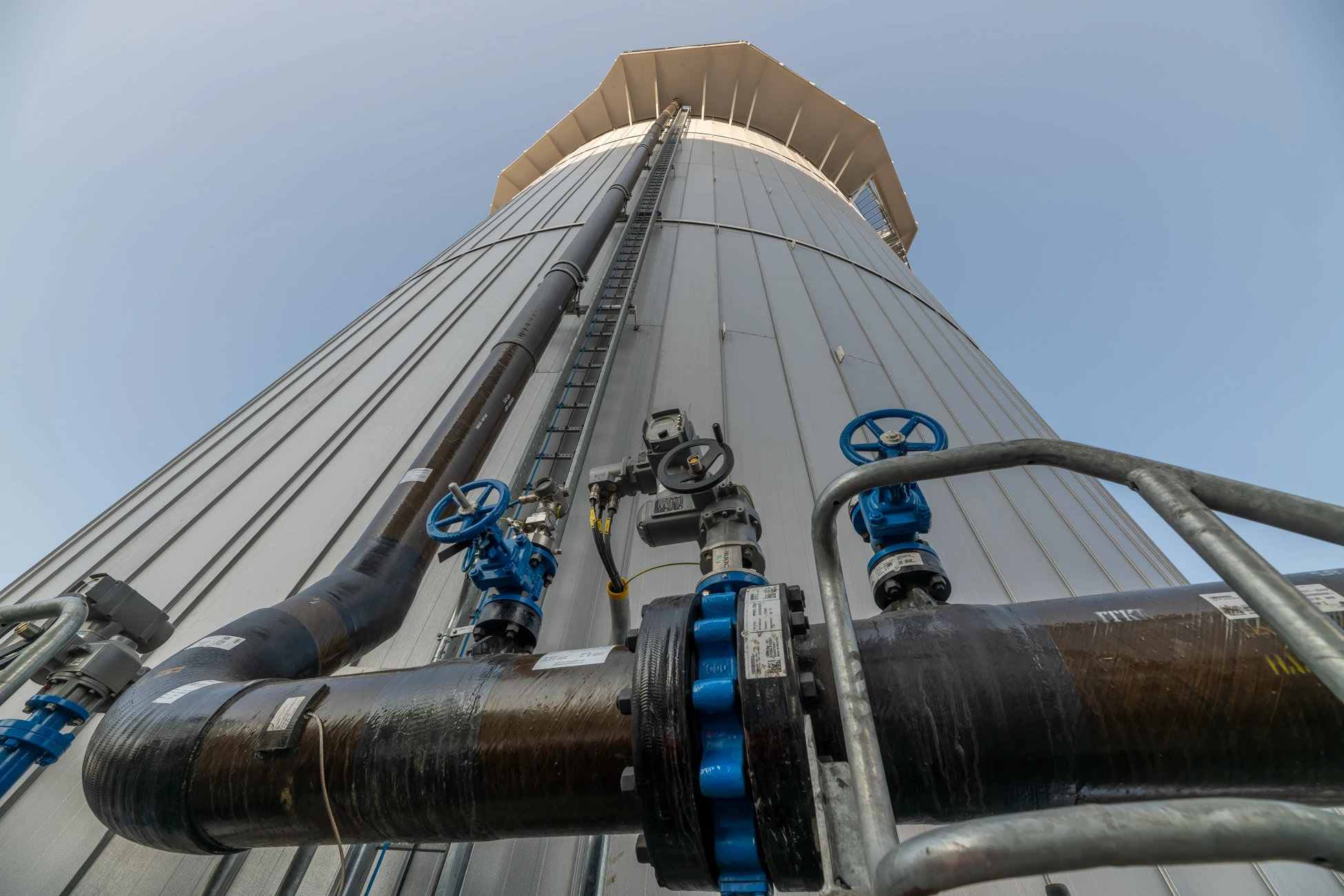

Tank terminal Rotterdam

Replacement and expansion of hot water network

Replacement and expansion of hot water network

For a Rotterdam tank terminal, Amerplastics realised a vapour recovery piping system using Bondstrand 7000M glass fibre reinforced epoxy (GRE) with bonded joints.

The project involves an extension of the existing vapour recovery network due to a new tank farm at the terminal.

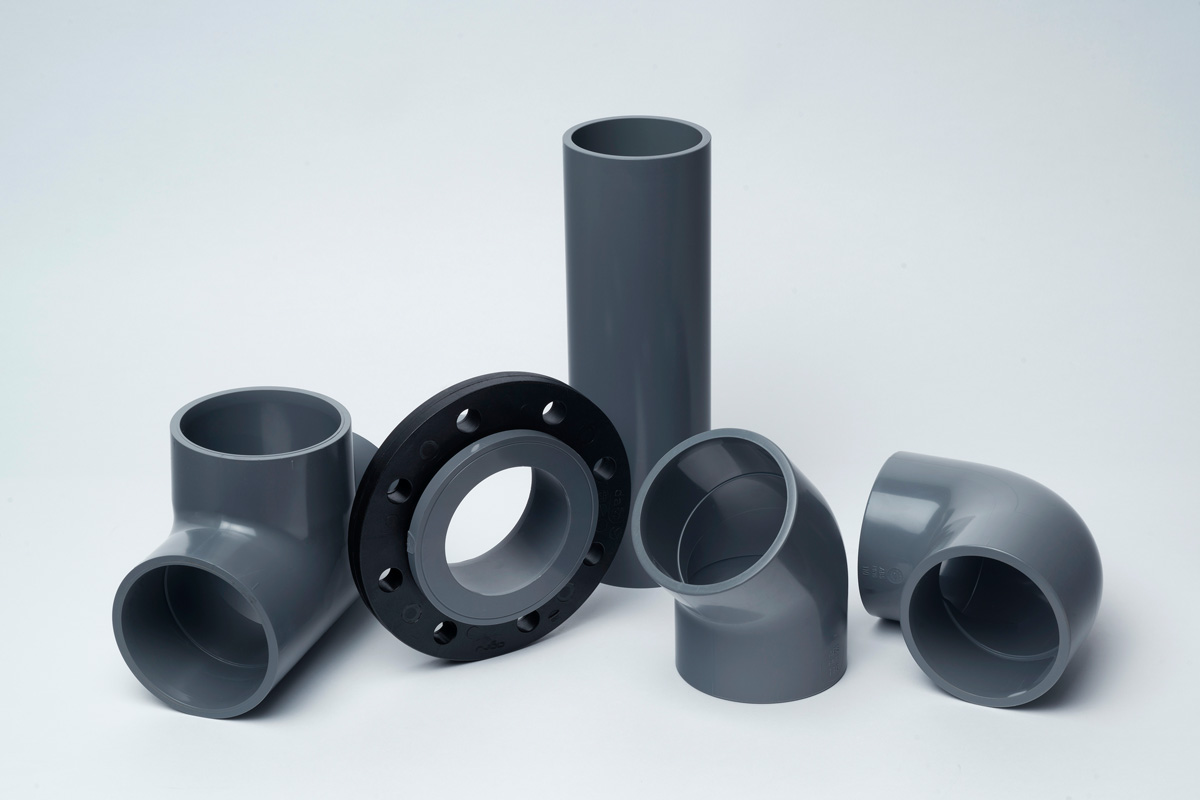

The project included the replacement and expansion of an existing carbon steel hot water network. The new GRE/PUR/PE hot water piping system (EPOGARD) will supply hot water to all laboratories in the pharmaceutical plant. GRE pipes are insulated with PUR and coated with a corrosion-resistant HDPE outer layer.

Thanks to GREs unique mechanical properties, expansion loops are not required. Thermal expansion is accommodated using concrete anchor blocks. Moreover, pressure losses are expected to be minimal due to the excellent wall roughness, which is beneficial for the pumps’ energy consumption.

In total, this project involved the supply and installation of 2,000 metres of insulated hot water supply and return pipes.

Piping system

Service: Vapour recovery (hydrocarbons / crude vapours)

Product: Bondstrand GRE series 7000M conductive

Diameter: 12 inches to 36 inches (300 – 900mm)

Operational conditions

Design pressure: 16 bar

Operational pressure: Max. 13.4 bar

Design temperature: 120 degrees Celsius

Operating temperature: 105 degrees Celsius

Benefits realised

- No expansion loops required

- Low pressure losses compared to conventional carbon steel system

Other projects

Other projects

Get in touch with Amerplastics experts

Get in touch with Amerplastics experts