Exhaust gas cleaning system

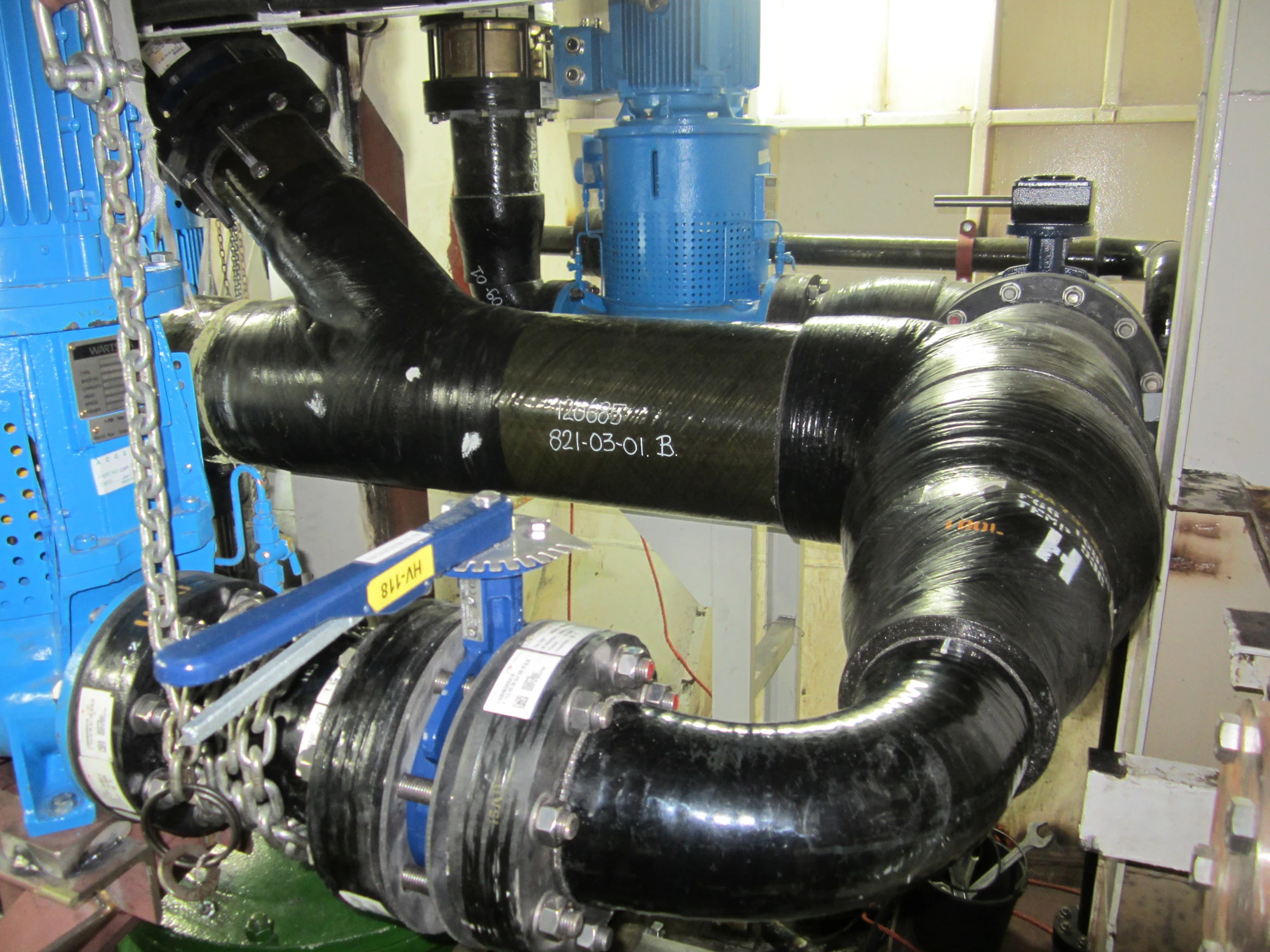

Amerplastics contributed to the realisation of exhaust gas cleaning systems on ro-ro ships BOTHNIABORG and BALTICBORG. For this, we used a Bondstrand 2000M glass fibre reinforced epoxy (GRE) piping system with Quick-Lock and Taper/Taper bonded joints.

The assignment included preparation of workshop isometrics, manufacturing of Bondstrand pipe spools, on-site assembly at the dry dock, supervision, and supply of the required GRE tools.

Economic and environmentally friendly solution

Economic and environmentally friendly solution

The exhaust gas cleaning system is an economical and environmentally friendly solution for complying with new SOx emission regulations. The scrubber system is designed to remove SOx from exhaust gases and operates using scrubber water.

The system operates continuously in a closed circuit, so the alkalinity of seawater is not a problem. The exhaust gases are sprayed into the scrubber and mixed with seawater with caustic soda (NaOH). The sulphur oxides in the exhaust react with this mixture and are neutralised. A small amount of water is drained from the closed circuit and treated to meet IMO requirements. The treated wastewater can be safely discharged into the sea without harming the environment.

Piping system

Service: Exhaust gas cleaning

Product: Bondstrand 2000M

Diameter: 4 to 16 inches (100 – 400 mm)

Operational conditions

Design pressure: 10 bar

Operational pressure: 3 bar

Design temperature: 93 degrees Celsius

Operating temperature: Ambient

Benefits realised

- Corrosion-resistant piping system

- Lower cost of ownership

- Maintenance-free

Other projects

Other projects

Get in touch with Amerplastics experts

Get in touch with Amerplastics experts